Helping companies

do good

The Good Plastic Company is a mission-driven

Organisation that has developed a technology to

repurpose plastic waste into sustainable materials.

Since 2018, we’ve transformed plastic waste into sustainable surface materials. Under our Polygood® brand, we create 100% recycled and recyclable products for the A&D industry, partnering with some of the world’s largest brands and organisations.

“Sustainability can scale — bridging technology, earth-friendliness, and business.”

— Dr William Chizhovsky, Founder and CEO

Our DNA:

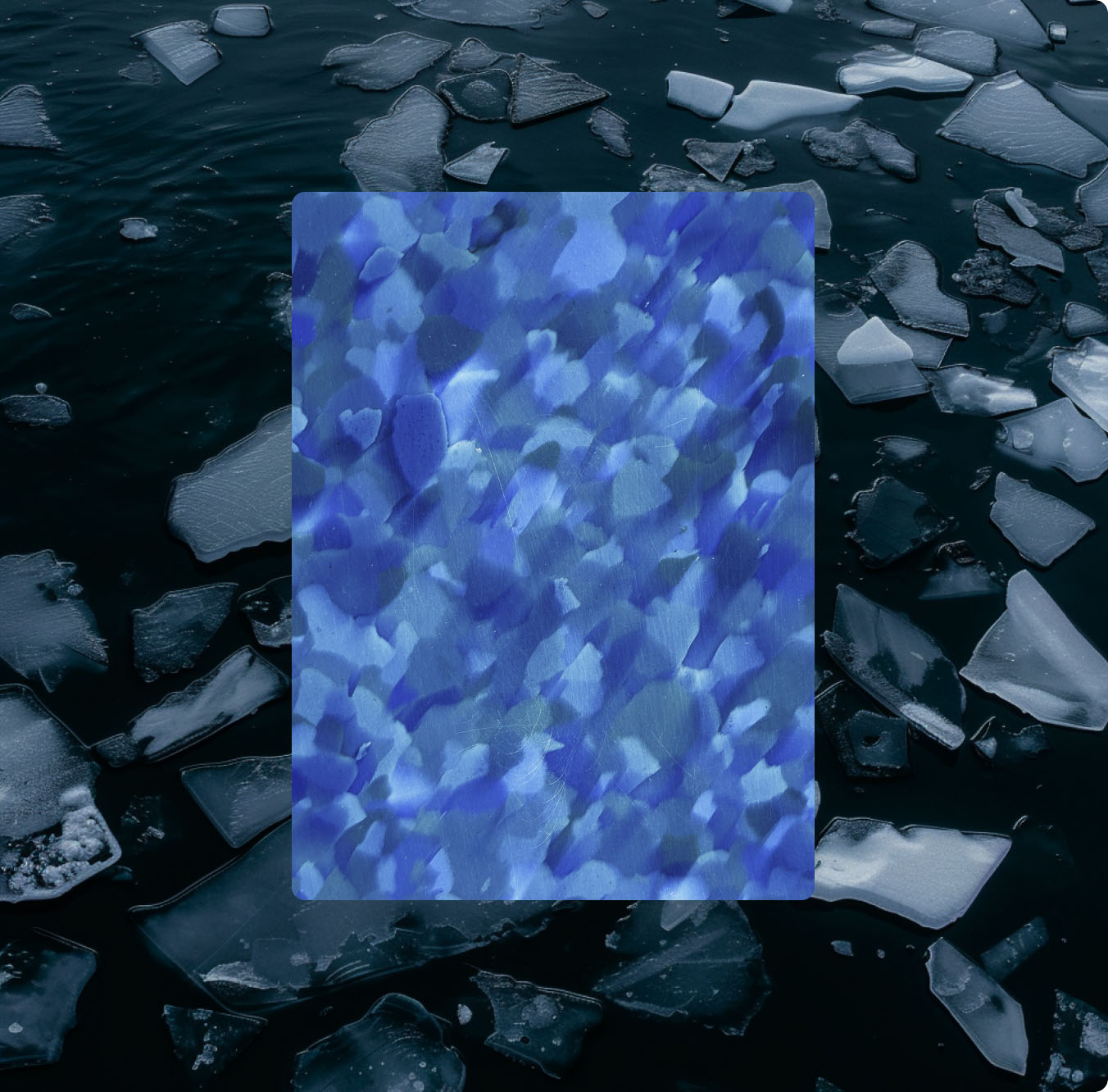

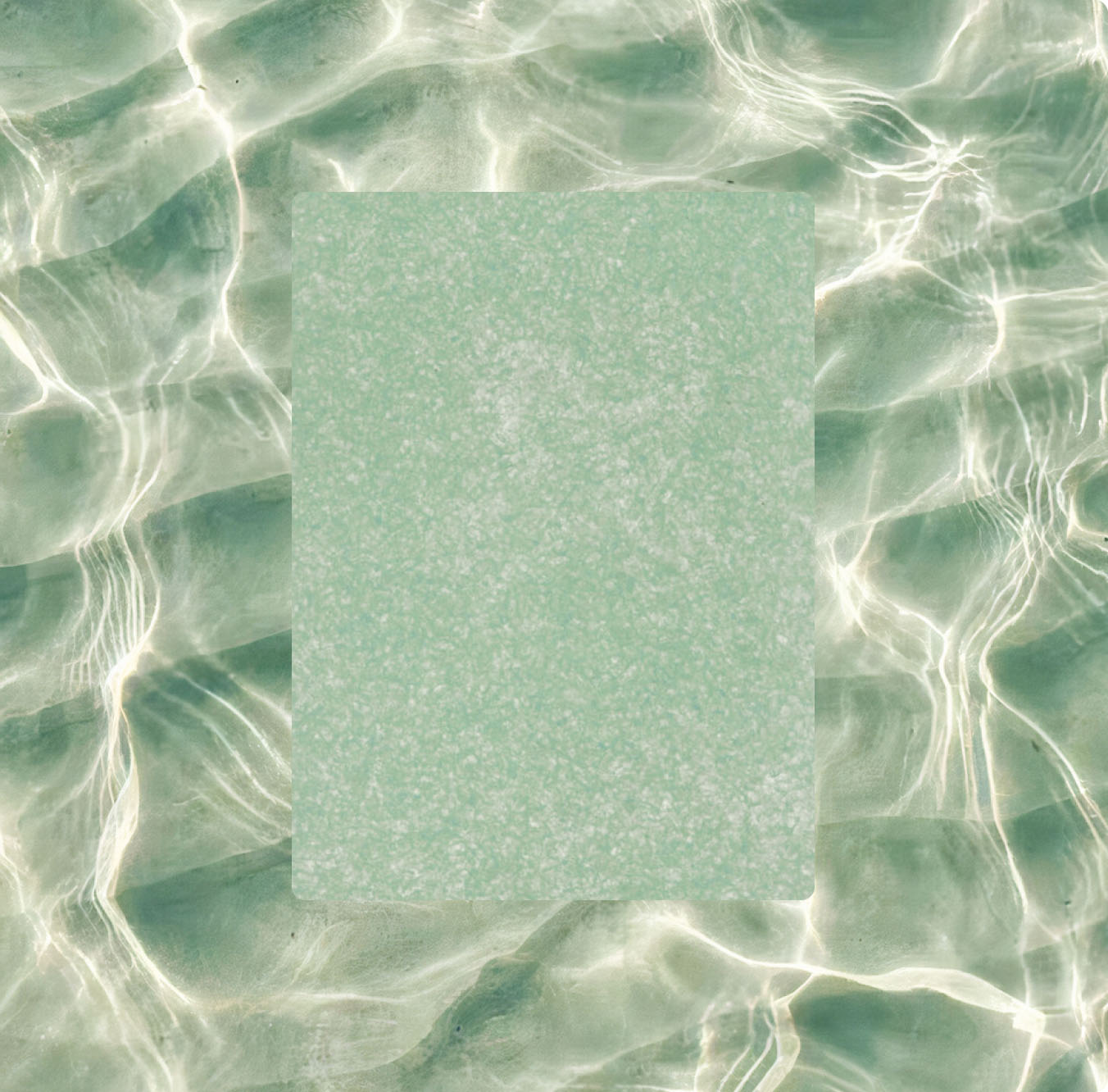

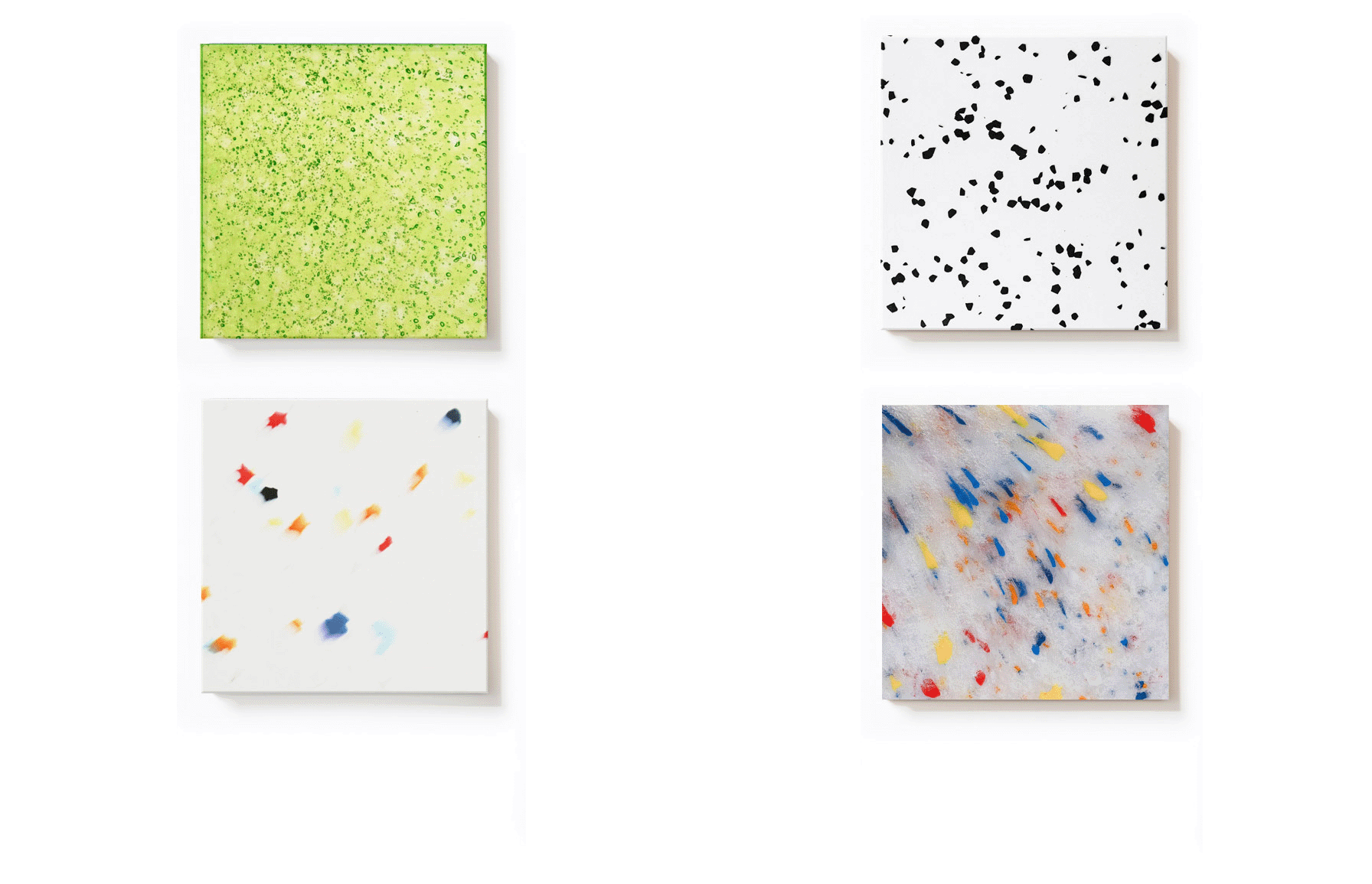

Polygood®

Our flagship product

Certified Sustainable Excellence

Supported by extensive laboratory testing and certifications to international standards including Cradle to Cradle®, ISO 9001, ISO 45001, and ISO 14001, we ensure the highest quality recycled panels under the Polygood® brand.

All locations

Factories

Official distributors