For Brands

We support your entire journey towards circular design.

Brands and sustainability

Brands around the world are implementing circular economy business models, driven by regulation and market demand. Their due diligence reviews pay increasing attention to their environmental, social and governance policies, the origin of materials, and working conditions. This sustainability transformation is a substantial challenge but also an opportunity for all companies in the supply chain.

Brands need a tangible way to demonstrate shared values to their customers and enhance brand affinity.

The Good Plastic Company offers complete, tailored solutions for brands seeking to implement sustainable materials. With expertise across numerous global projects, we’re a trusted partner in retail, hospitality, and beyond.

Your Sustainable Brand Journey Starts Here

Custom Patterns

Global Roll-Outs

Implementing your own waste

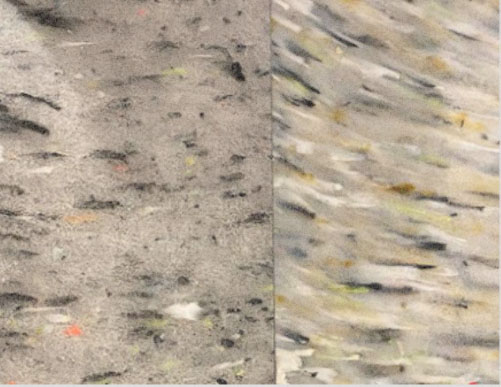

Custom Patterns

We created over 100 custom patterns with passionate brands.

Let us translate your vision into reality with customizable solutions that meet rigorous environmental standards. Our team can work with your designers to create panel colours and patterns that conveys a vision or brand.

Karl Lagerfeld

The fashion brand set a fashion-forward tone and complemented its brand identity with a custom Polygood® pattern simply called “Karl.” We worked with the Karl Lagerfeld team on the elegant yet modern combination of grey and blue patterns for their concept’s display fixtures.

Adidas

End Plastic Waste is an initiative by the sport apparel brand to develop products that either use recycled materials, are made to be remade, or are made with nature. Adidas extended that philosophy by choosing Polygood®, our 100% recycled surface material, to furnish their stores.

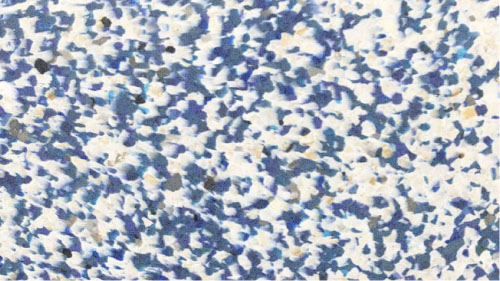

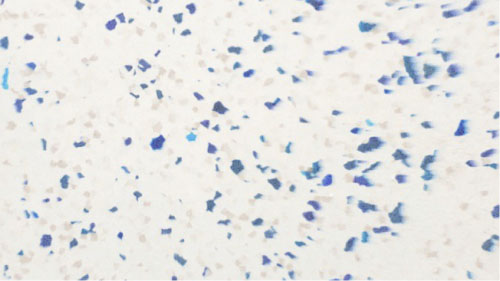

We took our traditional patterns and helped Adidas give their own twist. The resulting custom Polgood® patterns for store retail fixtures is a fresh mix of white and blue, both in light and dark variations. We varied the density and ratio of colours for the perfect look.

Global Roll-Outs

Our state-of-the-art facilities and proprietary technology ensures quality and consistency for large-scale, global rollouts of store locations requiring sustainable materials at volume.

40+ Nike stores

This long-standing partnership resulted in numerous patterns for several Nike concepts for stores globally.

Move to Zero

Move to Zero is Nike’s Journey toward zero carbon and zero waste. They are reimagining things top to bottom through sustainability and circularity, focusing on carbon, waste, water, and chemistry, aiming to hit targets by 2025. That includes their partnership with us, with 40-50% of store furnishings made from recycled plastic.

20 + Adidas stores

From Paris to Abu Dhabi, furniture, signage, and flooring made from Polygood® adorn Adidas stores worldwide.

30+ LUSH stores

LUSH uses Polygood® to create a welcoming space that showcases bath bombs and soaps, complementing the brand’s reputation for sustainable practices in cosmetics.

LUSH’s ambition to leave the world Lusher Than We Found It encompasses a bold pathway of how the company can make a meaningful contribution by removing all fossil fuel use from direct operations, including retail stores, offices, manufacturing sites and the vehicles by 2030. They are also working to reduce the climate and nature impact of their supply webs, while creating more opportunities for nature to thrive and help to remove emissions. LUSH aims for a net positive supply web by 2030.

Implementing your own waste

We collaborate with brands to transform their own waste into new products. A few success stories highlight just a few of the possibilities.

Nike Grind

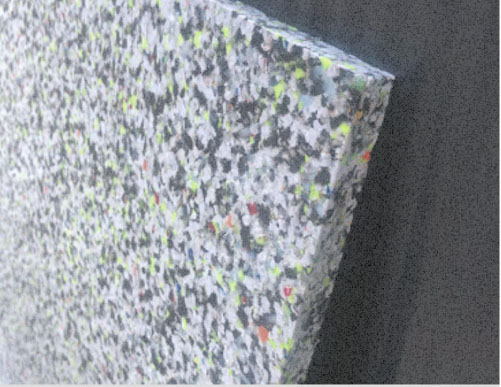

Together, The Good Plastic Company and Nike combined forces to find a way to use recycled soles of Nike Grind, their recycled polyurethane from footwear, to create entirely new Polygood® panels

The Good Plastic Company successfully developed and produced soft panels for use in some stores — impactful steps towards recycling polyurethane waste from apparel production and turning discarded materials into valuable resources.

Impact Acoustic

The Good Plastic Company and Impact Acoustic collaborated to create Coral Reef, a striking pattern in our Translucent Collection. We combined recycled CD cases and Impact’s leftover PET from their acoustic products. The result: panels tinted lagoon-blue, with vibrant orange speckles. This design not only showcases our commitment to sustainability but also symbolises our efforts to protect ocean ecosystems by repurposing post-industrial waste.

Sustainability Workshops

Visit our facility in the Netherlands for collaborative sessions on creating recycled plastic panels, aligning your goals with cutting-edge sustainable design, and value engineering for cost-effective, eco-friendly solutions.

We offer a deep dive into our process, educating you on the differences between plastic types and their unique characteristics. Together, we’ll create your own bespoke panels, opening up the Polygood® production process exclusively for our valued clients.

These hands-on workshops provide invaluable insights into sustainable manufacturing, empowering you to make informed decisions for your projects.

Full-Cycle Sustainability

Our free Take-Back Programme for used panels and offcuts is how we take responsibility for our product, even after its useful life.

Compliance and Transparency

Meeting international environmental and building standards, we pride ourselves on open communication and deep insights into our sustainable processes.

Continuous Optimization

Dedicated to improving sustainability metrics project after project, our engineers constantly refine designs, processes, and materials.

Tailored Project Management

Your project is our commitment. We work with all members of your design and implementation team as your single point of contact — from concept to completion — coordinating all aspects of sustainable material integration.

- Pattern colour, texture, shape and application advice

- Pattern tests available within one week

- Flexible production meeting large-scale project demands

- Logistics for rapid delivery

- Consistent quality and design across multiple locations

- Cost-effectiveness without compromising on design or environmental impact

- A dedicated team providing ongoing support and consistent materials throughout your rollout

Ready to Transform Your Interiors Sustainably? Find out more from our specialist

Viktoriia Siedova, Sales & Marketing Director

v.siedova@thegoodplasticcompany.com