Manufacturing & Technology

The Good Plastic Company transforms recycled plastic into valuable materials using unique, patented technology unlike anything the industry has seen before.

Research & development

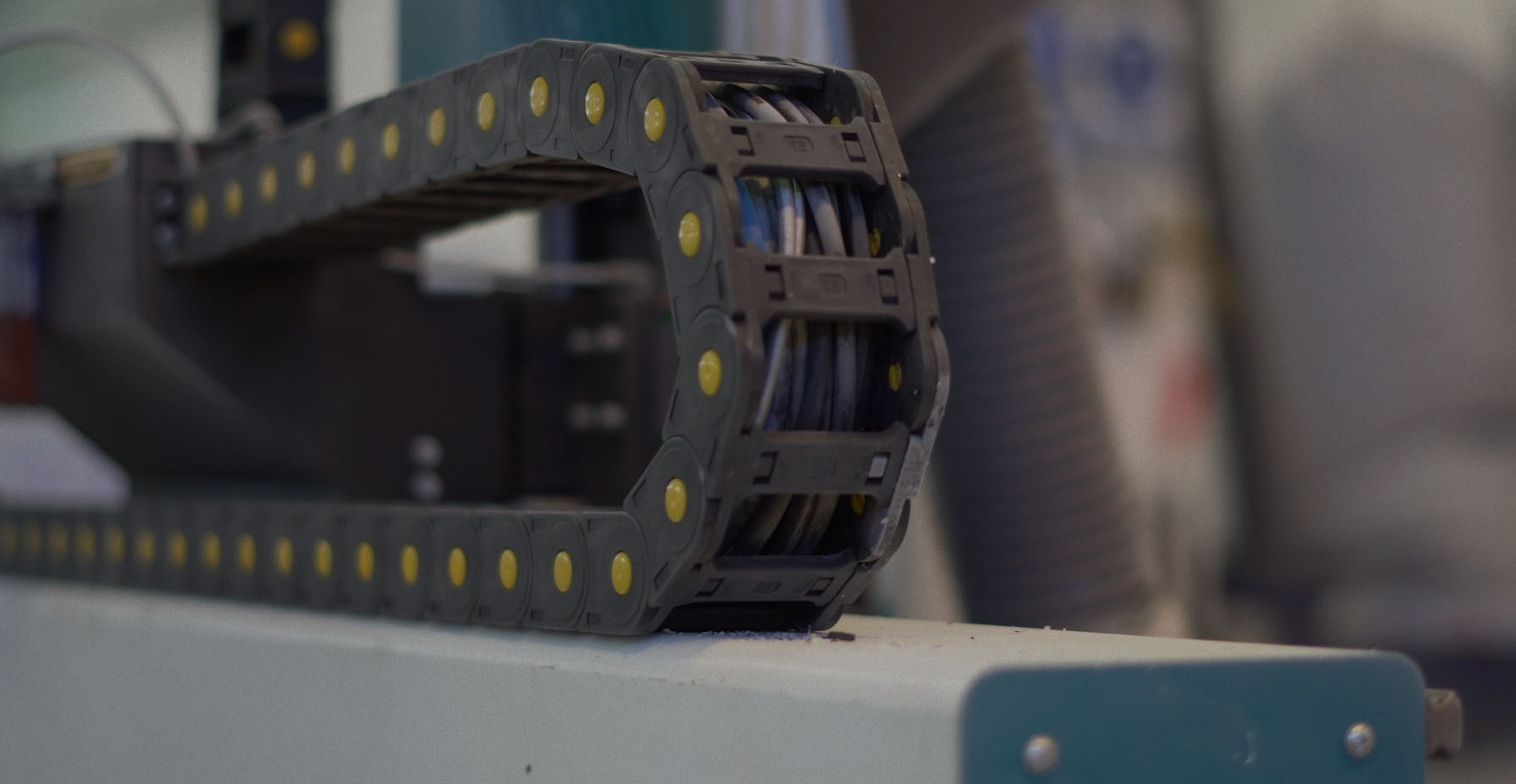

Processing plastic waste at an industrial scale required innovative machinery. Our engineers spent two years developing in-house equipment after finding no suitable off-the-shelf solutions from conventional suppliers.

Proprietary machinery

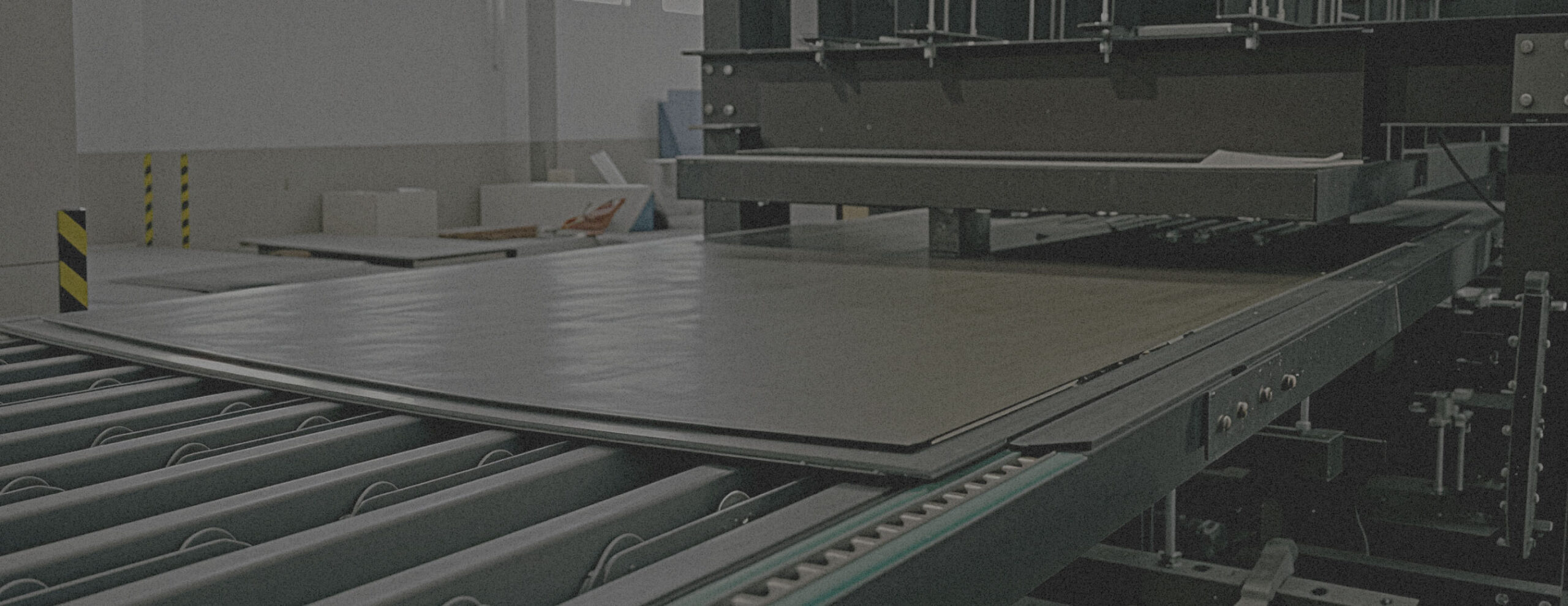

We pioneered a suite of equipment unlike anything seen before in the industry, offering precision and efficiency, meticulously measuring temperature and pressure to ensure high-quality panels. Today’s presses at our factory make the largest format panels on the market, at 2.8 x 1.4 metres.

Handling post-

consumer Waste

While competing recycled materials can contain low recycled raw material content, our technology enables us to master the art of plastic reuse. We source 70% of our materials from sturdy, post-consumer waste (like refrigerator panels and CD cases) and 30% from post-industrial waste.

Variety & scalability

Our equipment allows us to produce high-quality Polygood® panels from diverse waste streams. And because our flagship product is made from a single type of recycled polystyrene, we are proud that every panel consists of 100% recycled plastic and is 100% recyclable at the end of their lifespan.

This technology also handles 80% of plastic types, expanding possibilities for plastic reuse. Meanwhile, we continue to transform vast amounts of plastic waste into valuable resources, producing over 1,000 tonnes of Polygood® annually—equivalent to 50,000 m² or nine football fields.

Find out more from our specialist

Nick Petrychenko, Head of Production Operations

n.petrychenko@thegoodplasticcompany.com